In industrial fields such as chemical synthesis, pharmaceutical production, and natural product extraction, many production workshops harbor an "invisible risk"—explosive environments. Volatile organic solvents permeate the air, or fine combustible dust suspends and accumulates. Once mixed with oxygen in a specific ratio, encountering electric sparks, high-temperature surfaces, or electrostatic discharge, it may instantly trigger deflagration accidents with severe consequences.

In such high-risk workplaces, how to conduct large-scale, high-efficiency chromatographic separation and purification while ensuring production safety? The explosion-proof industrial preparative liquid chromatography system is a professional solution designed specifically for this critical need. Through comprehensive explosion-proof design and structural modifications complying with strict safety standards, it enables the chromatographic separation process to operate stably and continuously in flammable and explosive environments, balancing purification efficiency and intrinsic safety. It has become an indispensable technical guarantee in high-risk process links.

I. Science Corner: Why Do We Need an "Explosion-Proof" Industrial Preparative Liquid Chromatography System?

Where Does the Risk Come From?

In the sample purification process, a large number of organic solvents such as methanol, ethanol, acetonitrile, acetone, and n-hexane are used, which are highly volatile and flammable. The vapor generated by their volatilization can form an explosive gas environment within a certain concentration range. At the same time, conventional electrical equipment (such as motors driving pumps, instrument switches, operation controllers, etc.) may generate electric sparks, electric arcs, or local high-temperature surfaces during normal startup/shutdown, operation, or malfunction. Once these potential ignition sources come into contact with the explosive atmosphere, they are likely to cause combustion or explosion, posing significant safety hazards.

What is "Explosion-Proof"?

The core goal of explosion-proof design is not that the equipment can withstand internal explosion impacts, but to prevent the formation of explosive conditions at the source or limit their impact through a series of engineering measures. Such designs are essentially proactive and preventive safety measures, usually adopting protective types such as flameproof, increased safety, intrinsic safety, positive pressure, or encapsulation. They eliminate explosions in hazardous environments by controlling electrical sparks, suppressing surface temperatures, or isolating combustibles from ignition sources.

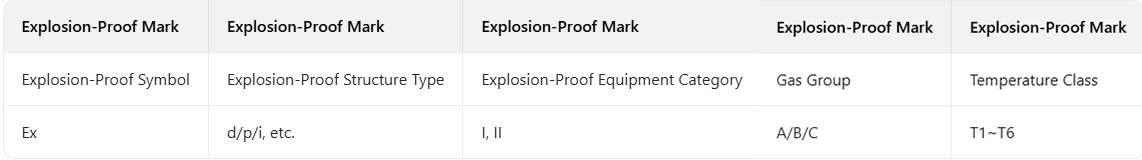

What Does the Explosion-Proof Rating "Exd IIB T4" Mean?

This is the core safety mark of our system. Let's break it down:

Ex: Represents the explosion-proof symbol of China and the International Electrotechnical Commission (IEC).

d: Represents "flameproof type", which can isolate existing ignition sources. In addition, the "positive pressure type (p)" is also available in industrial preparation systems, with better explosion-proof effect than the "flameproof type (d)".

IIB: Indicates that the equipment is suitable for environments other than coal mines and underground use, and can be used in gas environments with relatively high hazards such as ethylene and propylene (excluding IIC gases such as hydrogen and acetylene).

I: Electrical equipment for coal mines and underground use.

II: Electrical equipment other than that for coal mines and underground use.

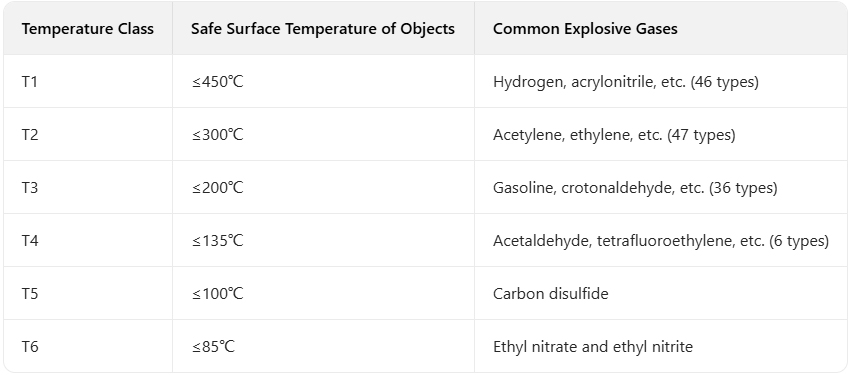

Classification of Gas Temperature Classes

Divided into six groups from T1 to T6 according to the maximum surface temperature of the equipment, as shown in the following table:

T4: Indicates that the maximum surface temperature of the equipment will not exceed 135℃, which is a relatively high safety level among temperature classes (T1 is the highest, T6 is the lowest).

II. Key System Components

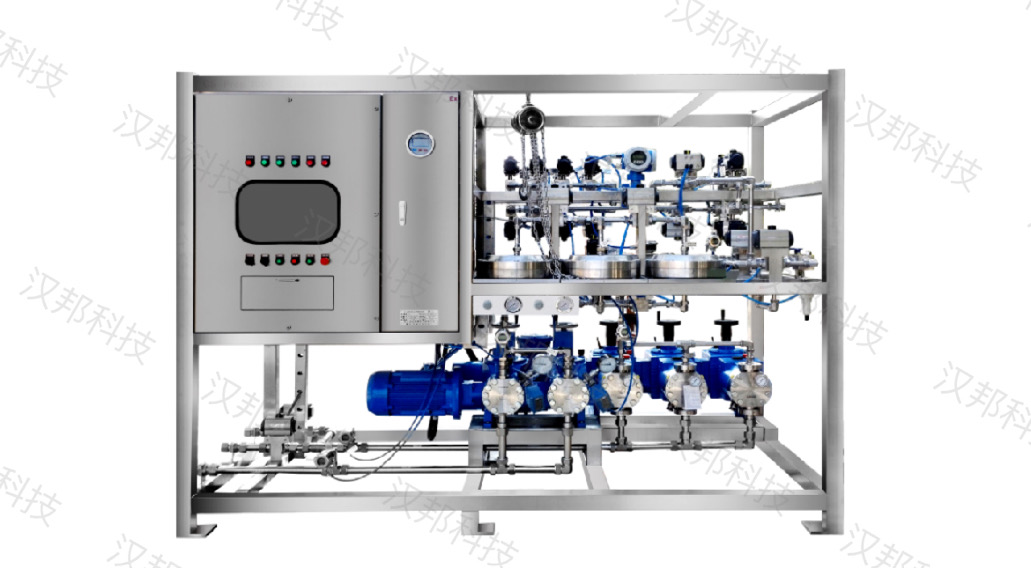

Overall Explosion-Proof Design

The system adopts a system-level overall explosion-proof design concept. From the intelligent positive pressure explosion-proof electrical cabinet as the control core to key components for transportation such as the Riva diaphragm pump and its drive motor, all units that may generate ignition sources in hazardous areas adopt corresponding explosion-proof types. At the same time, all core explosion-proof components hold explosion-proof certificates issued by authoritative institutions, ensuring the integrity and compliance of the overall system design and certification.

Note: Whether to adopt overall explosion-proof depends on the actual project requirements.

Safety Certification

The entire system meets Ex IIB T4 (positive pressure explosion-proof type) and has IP65 protection level. This indicates that the equipment can not only be safely used in common combustible gas environments (IIB class) but also its maximum surface temperature is strictly controlled (T4 ≤ 135℃). The dual certification ensures that the system can operate stably, safely, and long-term in complex and harsh industrial environments.

Riva Diaphragm Metering Pump

Equipped with a three-pump head diaphragm metering pump for material transportation, it features stable material delivery and low pulsation; adopts a double-layer diaphragm design with PTFE diaphragms, ensuring no medium leakage, safety, and reliability; the metering accuracy can reach ±1.0% (within the pump's working range and under specific pressure conditions); uses metal ring sealing technology instead of ordinary packing sealing, which can ensure long-term high metering accuracy and sealing effect.

Intelligent Control

To ensure the stability and efficiency of large-scale purification production, the system integrates Siemens PLC and WinCC chromatography workstation, realizing full-process automation from sample injection to fraction collection, minimizing manual intervention, liberating operational manpower, and avoiding human errors.

At the same time, the system deeply integrates a data integrity solution, and its software meets the core requirements of FDA 21 CFR Part 11 regulations. Through the implementation of electronic signatures, full-process audit trails, and strict three-level authority management, it ensures the authenticity, integrity, and traceability of all operational data, allowing your production batch records to easily cope with strict quality audits at home and abroad.

In addition, in terms of system structure, all components in direct contact with liquids, such as pipelines, valves, pump heads, and column interfaces, are made of high-performance materials such as 316L stainless steel, PTFE, or PEEK. These materials have excellent chemical inertness and corrosion resistance, and can withstand the erosion of various organic solvents, acids, alkalis, and high-salt mobile phases, fundamentally avoiding sample loss and system failures caused by material contamination or degradation. At the same time, all key materials provide corresponding material certification documents (such as ASME/ASTM reports for 316L stainless steel). For pharmaceutical applications, we can further provide USP Class VI biocompatibility reports for key polymer components (such as PTFE, PEEK), supporting process validation and drug registration, ensuring that their composition and performance comply with process and safety specifications, and providing reliable guarantee for the long-term stable operation of the system and product purity.

DAC Dynamic Axial Compression Column

We offer DAC series chromatographic columns with diameters ranging from 50mm to 2000mm. As a star product in the field of preparative chromatography, it not only has the all-round properties of automatic column packing, maintaining column pressure, and self-column unloading but also integrates the functions of a chromatographic column and a column packer. It ensures the continuity, uniformity, stability, and compactness of the column bed, effectively avoiding the potential risk of column bed collapse, and providing guarantee for continuous and stable production activities.

Hanbon Technology's DAC technology ensures efficient, uniform, and stable chromatographic column packing, and has been recognized by a large number of customers for its high column efficiency and excellent separation effect. The launch of the explosion-proof design ensures that this precise and powerful system can operate safely, stably, and continuously under the harshest working conditions, truly escorting industrial production. It ensures the stable reproduction of column efficiency during the scale-up process from laboratory scale to industrial production scale, reducing process transfer risks.

III. Application Scenarios

This explosion-proof industrial preparative liquid chromatography system is specially designed for high-demand, high-risk large-scale separation and purification, and is mainly applicable to the following key fields:

1. Large-Scale Purification of Active Pharmaceutical Ingredients (APIs)

Suitable for large-scale, high-purity refinement of key APIs in the pharmaceutical industry. The system can meet cGMP regulatory requirements, ensuring the consistency and repeatability of the separation process, and providing guarantee for the quality and compliance of final drugs.

2. Separation of Fine Chemical Intermediates

For high-value-added fine chemicals, special material monomers, or complex synthetic intermediates, it achieves efficient and precise separation and purification, improving product purity and yield to meet high-end market demand.

3. Extraction of High-Value Components from Natural Products

Suitable for efficiently separating and extracting active ingredients, reference substances, or high-value compounds (such as health product raw materials, cosmetic active substances, etc.) from natural sources such as plants and microorganisms. The system has strong compatibility and can gently process thermosensitive substances.

IV. Conclusion

Hanbon Technology's explosion-proof industrial preparative liquid chromatography system is not only a precision equipment for efficient separation and purification but also a reliable safety fortress built in flammable and explosive environments. It systematically overcomes the long-standing industry challenge of balancing "efficiency" and "safety", enabling you to fully release production capacity potential while strictly complying with safety norms and regulatory requirements. The core value of this system is not only to "bridge the gap" but also to "build a reliable bridge connecting process development, safety compliance, and large-scale production".